BYG / MEK Course 11331

Course Responsible:

Holger Hundborg Koss (BYG)

Christian Berggreen (MEK)

Departments of Civil & Mechanical Engineering

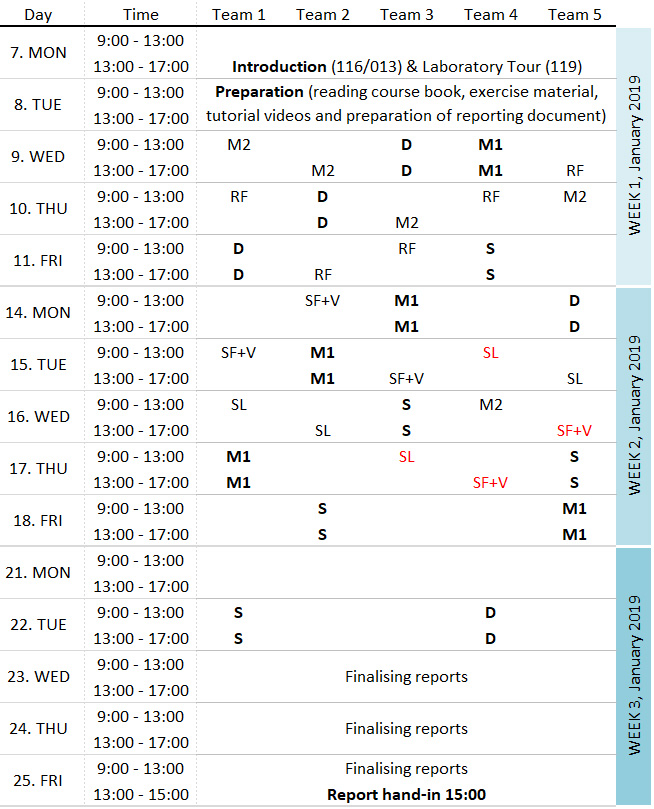

Schedule

3-weeks course in January. Course start is on January 7, 2019 at 1:00 p.m. with the introductory lecture in building 116, room 013. Hereafter, we will visit the laboratories to give you a first impression of the experiments you are going to perform within this course.

General Specifications

5 ECTS points ; Master (MSc) students ; maximum number of participants: 30 ; Language: English ; IMPORTANT: all students must have passed the safety introduction to be allowed working in DTU-Byg's laboratories. The introduction video and quiz is available online in Portalen (here).

Course Material

Detailed description of the exercises, additional information regarding the course and background reading material is provided in the accompanying course book with compendium. A pdf-copy of the course book will be uploaded on CampusNet.

Course Objectives and Background

The course is intended to provide practical experience in using experimental methods to describe and analyse loading on civil and mechanical engineering materials and structures and their response in terms of forces, stresses and deformations. A central aspect is to introduce the students to the corner stones of experimental investigation, i.e. proper preparation, systematic testing and accurate documentation and analysis. With this course the students should be prepared for experimental studies in other fundamental and advanced courses and for experimentation in e.g. Master projects. Furthermore, the course strives to convey basic understanding of the “design assisted by testing” concept and background of the semi-probabilistic design philosophy as used in Eurocodes.

The course is primarily offered to students enrolled in the Civil Engineering, Engineering Design and Applied Mechanics Master programs. This course is similar to the existing course on Experimental Solid Mechanics (41811) at MEK.

Learning Objectives

A student who has met the objectives of the course will be able to:

-

Understand the purpose of experimental investigation in civil and mechanical engineering.

-

Understand the choice of methods for experimental testing, their strengths and shortcomings and the evaluation of the result quality.

-

Interpret the results as stochastic variables and processes and to apply statistical methods to calculate characteristic values from the experimentally acquired data used in semi-probabilistic structural design.

-

Compare experimental observations with theoretical predictions, and provide explanations or hypotheses for deviations among these.

-

Demonstrate practical experience with the selected experimental methods, performance care and accuracy and with proper and concise documentation.

-

Describe the purpose of specific experiments, and conclude rationally and balanced on the results.

-

Collaborate with others on carrying out experiments, including contributing actively to complete the experiment in time, and with proper outcome to all participants.

-

Produce written experimental reports that are well structured, complete, clear and concise, critically assessing / concluding, and otherwise confirming to accepted standards for written presentation in the subject area.

Content & Schedule

The practical course content consists of eight different experiments in which material and structural properties as well as stochastic loading shall be investigated. The tests have been selected to give a broad overview on testing methods and physical effects structural and mechanical engineers have to deal with. The experiments shall be prepared, performed and documented by teams of 4 to 6 students (no more than 5 teams in total!).

The experiment time schedule of the course for January 2019 assuming five teams is given below. Please bear in mind that the time schedule might be changed during the course period. Any changes and updates will be published on this page and announced via CampusNet (please check your Email on a regular basis!). More detailed description of the exercises is given in the course compendium.

Experiment Time Schedule for Course 11331 - January 2019 (2nd revision)

NOTE: Only the latest change - if any - will be indicated.

New time slot for exercise is indicated in red.

Time Schedule Legend:

(number indicates the building in which exercise is hold)

S - Static bending of an beam and flexion and torsion of a thin-walled tube (119)

M1 - Load-deformation testing on a standard metal specimen (119)

D - Load-deformation testing on a flat metal specimen (119)

M2 - Load-deformation testing on a standard concrete specimen (119)

RF - Deformation testing on reinforced concrete beam (119)

SF+V - Static load deformation and free vibration decay (119)

SL - Stochastic loading (119)

For the course an accompanying course book will be issued with detailed descriptions of the test setups, background information, analysis guidance and general course information. The different experiments are briefly described below:

1.) Strain Gauge Exercise

Static Bending of a Beam

This exercise will be similar to the existing one in the experimental mechanics course 41811 at MEK. This exercise will deal with the use of strain gauges in a beam loaded in bending. Two strain gauges (one on top and another in the bottom) will be mounted in this beam. A known load will be applied and the displacement as well as the strain on the upper and lower surface of the beam recorded for further analysis and reporting.

This exercise will be similar to the existing one in the experimental mechanics course 41811 at MEK. This exercise will deal with the use of strain gauges in a beam loaded in bending. Two strain gauges (one on top and another in the bottom) will be mounted in this beam. A known load will be applied and the displacement as well as the strain on the upper and lower surface of the beam recorded for further analysis and reporting.

Flexion and Torsion of Thin-Walled Tube

This exercise will deal with the use of strain gauges in a thin-walled tube subjected to flexion-torsion loading. The main task in this exercise is to use rosette strain gauges for determining the principal stresses and their principal components in the thin-walled tube loaded under torsion, flexion and flexion-torsion. Furthermore, within the task in this exercise, the mounting and connecting of gauges as well as the use of software for data analysis will be included.

This exercise will deal with the use of strain gauges in a thin-walled tube subjected to flexion-torsion loading. The main task in this exercise is to use rosette strain gauges for determining the principal stresses and their principal components in the thin-walled tube loaded under torsion, flexion and flexion-torsion. Furthermore, within the task in this exercise, the mounting and connecting of gauges as well as the use of software for data analysis will be included.

2.) Material Testing (M1): Load-deformation testing on a standard metal specimen

Determination of the mechanical properties of materials. Properties such as, elastic modulus, yield point, fracture point, ultimate failure strength, and others relevant have to be determined. The elastic properties (E, v) will be determined using specimens with strain gauges. Strength properties will be determined by pulling the specimens up to failure and monitor the failure stress and strain. For this exercise, standard metal specimens will be tested in tension.

Determination of the mechanical properties of materials. Properties such as, elastic modulus, yield point, fracture point, ultimate failure strength, and others relevant have to be determined. The elastic properties (E, v) will be determined using specimens with strain gauges. Strength properties will be determined by pulling the specimens up to failure and monitor the failure stress and strain. For this exercise, standard metal specimens will be tested in tension.

3.) Digital Image Correlation System (D): Load-deformation testing on a flat metal specimen

This exercise will deal with the use of the ARAMIS system. ARAMIS system is widely used in experiments at MEK and BYG. A flat painted specimen (steel and/or aluminum) will be loaded in compression and monitored with ARAMIS system. Due to compressive loads, the specimen will buckle and ARAMIS will be able to capture these out-of-plane displacements which are quite interesting for the students.

This exercise will deal with the use of the ARAMIS system. ARAMIS system is widely used in experiments at MEK and BYG. A flat painted specimen (steel and/or aluminum) will be loaded in compression and monitored with ARAMIS system. Due to compressive loads, the specimen will buckle and ARAMIS will be able to capture these out-of-plane displacements which are quite interesting for the students.

4.) Material Testing (M2): Load-deformation testing on a standard concrete specimen

The compressive strength will be tested on several standard concrete specimens. Main focus of this test is the statistical description of the measurement results. The characteristic value of the compressive strength, as requested for structural design with EUROCODE, shall be calculated as a fractile of the distribution density. Depending on the age of the test specimens suitable corrections for 28-day strength comparison shall be made.

The compressive strength will be tested on several standard concrete specimens. Main focus of this test is the statistical description of the measurement results. The characteristic value of the compressive strength, as requested for structural design with EUROCODE, shall be calculated as a fractile of the distribution density. Depending on the age of the test specimens suitable corrections for 28-day strength comparison shall be made.

5.) Structural Deformation (RF): Deformation testing on reinforced concrete beam

Bending of reinforced concrete beams commonly found in civil structures. A simple reinforced concrete beam will be loaded for bending. The deformation of the beam will be monitored on dial indicators and documented with the applied loading. Both values are used to calculate the elastic bending stiffness. The beam will be loaded until failure. The establishment of cracks and their propagation shall be documented together with the deformation. Depending on the number of test specimens available different loading types will be tested and compared.

Bending of reinforced concrete beams commonly found in civil structures. A simple reinforced concrete beam will be loaded for bending. The deformation of the beam will be monitored on dial indicators and documented with the applied loading. Both values are used to calculate the elastic bending stiffness. The beam will be loaded until failure. The establishment of cracks and their propagation shall be documented together with the deformation. Depending on the number of test specimens available different loading types will be tested and compared.

Tutorial Video on YouTube: https://www.youtube.com/watch?v=3vyGDvkA-q8

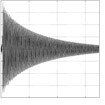

6.) Static and Dynamic Properties (SF+V): Static deformation and free vibration decay

The static properties of a steel frame structure will be determined by static loading of the structure at different positions and registering the resulting deformation. The collected data are used to calculate the overall stiffness of the structure and to estimate the first vibration mode shape. Releasing the structure from pre-deformation the hereafter decaying vibration of the frame will be measured with accelerometers. The time history of the free decay test is used to calculate the structural damping.

The static properties of a steel frame structure will be determined by static loading of the structure at different positions and registering the resulting deformation. The collected data are used to calculate the overall stiffness of the structure and to estimate the first vibration mode shape. Releasing the structure from pre-deformation the hereafter decaying vibration of the frame will be measured with accelerometers. The time history of the free decay test is used to calculate the structural damping.

Tutorial Video on YouTube: https://www.youtube.com/watch?v=tdfBuZLte0I

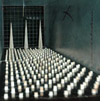

7.) Stochastic Loading (SL): Base-balance measurement of wind-induced loading of a vertical pylon

This exercise addresses the loading aspect in civil and mechanical engineering. If structural safety is defined by S < R (stress smaller than resistance) the stochastic nature of loading will be examined in this exercise. A vertical pylon or shaft-like structure will be mounted in a wind tunnel test setup fixed at the bottom to a high-frequency force balance. The time series of the measured base forces and moments will be transformed into stress of a generic structure. Statistical methods shall be applied to describe the probability that S < R by using data from exercises testing material strength.

This exercise addresses the loading aspect in civil and mechanical engineering. If structural safety is defined by S < R (stress smaller than resistance) the stochastic nature of loading will be examined in this exercise. A vertical pylon or shaft-like structure will be mounted in a wind tunnel test setup fixed at the bottom to a high-frequency force balance. The time series of the measured base forces and moments will be transformed into stress of a generic structure. Statistical methods shall be applied to describe the probability that S < R by using data from exercises testing material strength.

Tutorial Video on YouTube: https://www.youtube.com/watch?v=XXzZxojGKBU